Toolmaking

We give your project the right shape

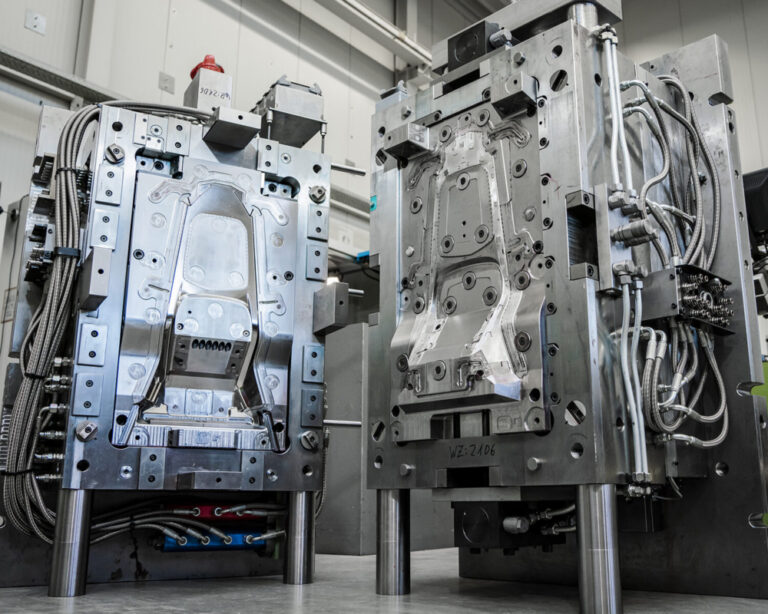

The close collaboration in our team and the constant exchange of information with the design department, injection moulding production and customer support constitute the basis for optimum mould construction. Our own toolmaking department, supplemented by long-standing partners at home and abroad, contribute all their experience to produce high-precision injection moulds.

We manage the entire tool production chain: from design to production monitoring to sampling, in order to guarantee the quality and process capability of the tools.

Our integrated mould construction always supports production with a high level of know-how. Thanks to software-supported control of the maintenance cycles and a traffic light system, changes or due repairs are visualised.

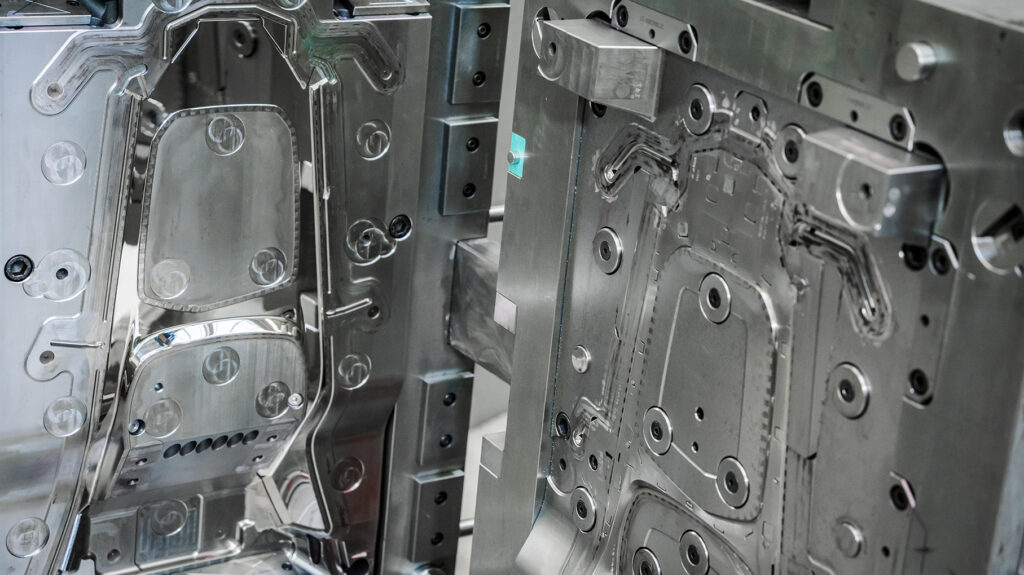

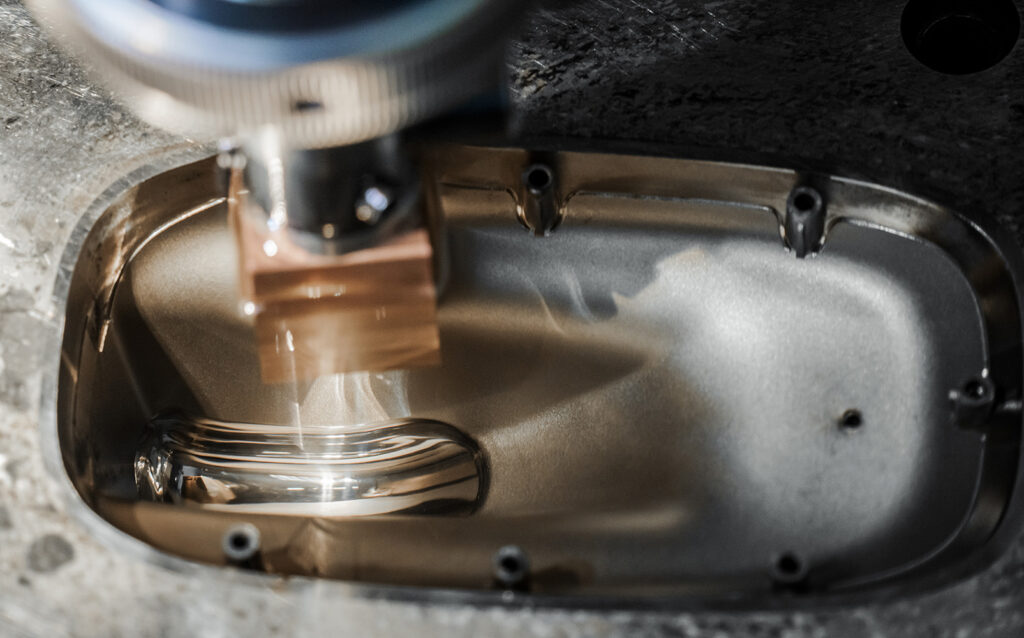

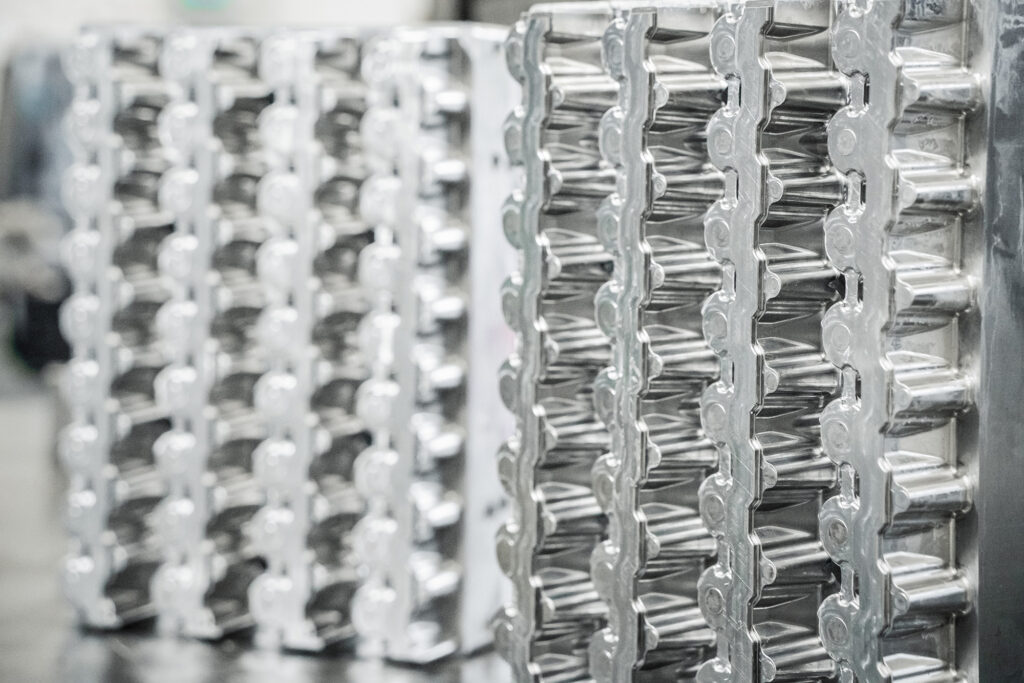

In our own tool shop, we have all the technical prerequisites to build, maintain or repair tools. Wire-cut EDM, CNC die-sinking EDM as well as CNC milling are naturally part of our know-how to automatically produce tools with high precision even for complex shapes. For conventional machines, the craftsmanship of our specialists comes into play.

In addition to the creation of new moulds, the existing ones are maintained, conserved, serviced and safely stored by our experts. We develop the necessary maintenance plans and determine the spare parts requirements to ensure the usability or availability of the moulds.

Ultrasonic cleaning allows the moulds to be thoroughly cleaned and all residues to be gently removed.

When taking over external projects, the inspection and initial acceptance of the supplied moulds takes place in our toolmaking department. After sampling in production, we guarantee further production on our machines to the usual quality.