Construction

The product design team translates our customers' ideas into perfect 3D geometries.

After in-depth consultation and development, our specialists accompany the customers in the realisation of their plastic products.

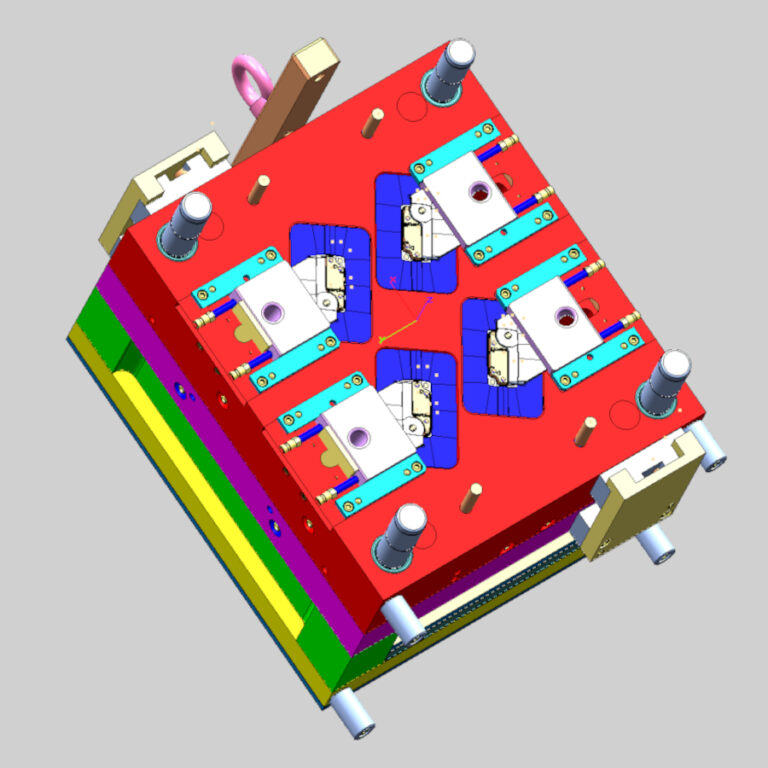

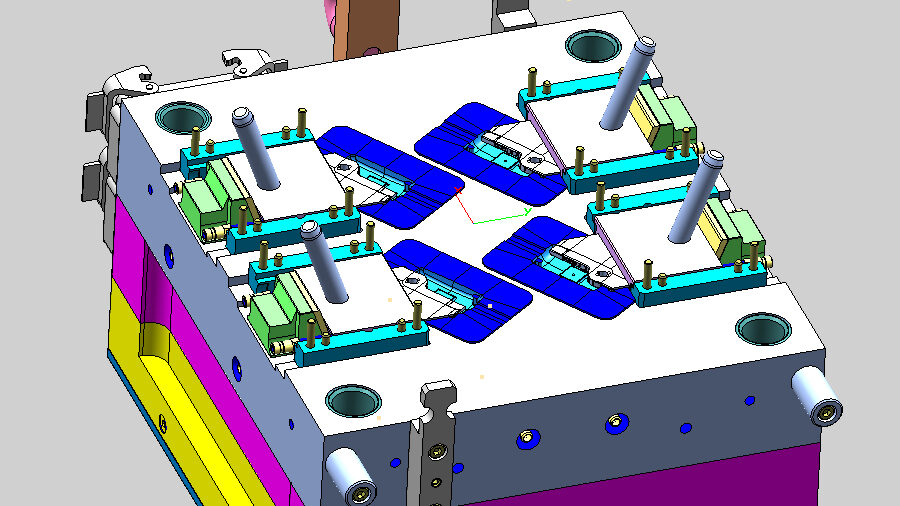

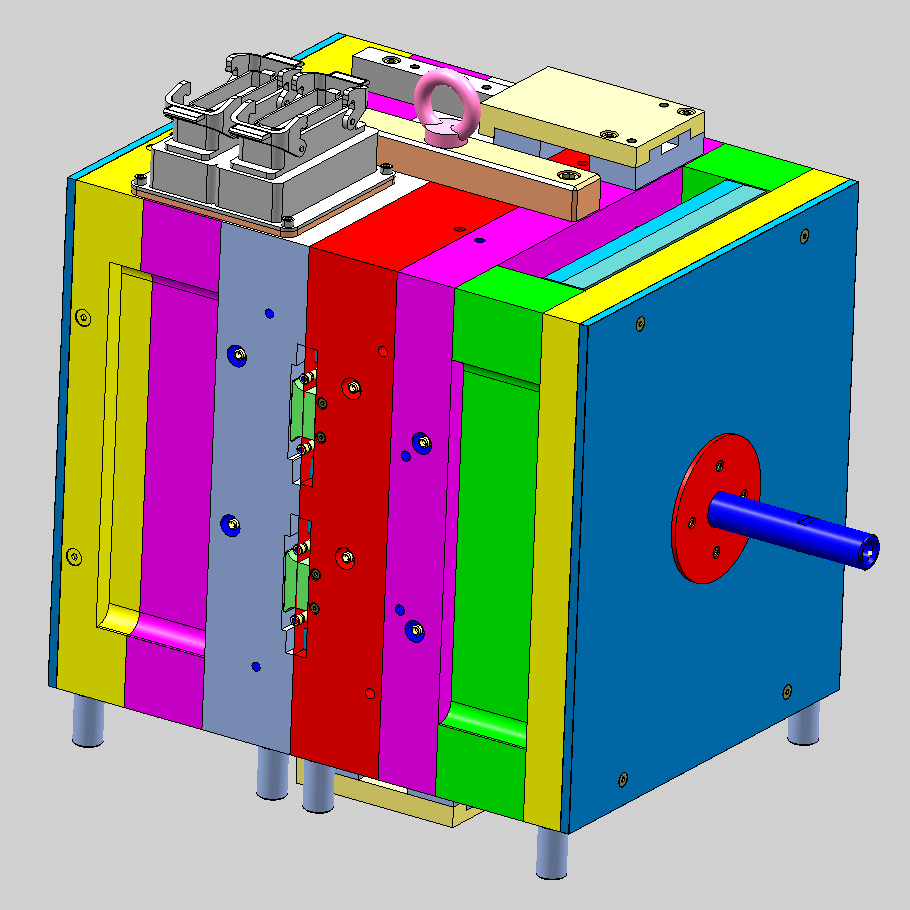

From the first drawing to the finished tool, the entire development process is supported by using suitable software. The customer’s design data can be taken over, evaluated and checked by our technicians. If necessary, the construction can be completely realised by our team directly from a first sketch.

Tool-, production- and assembly-specific concerns are integrated into the design. In this way, design and function are combined to create an optimal product.

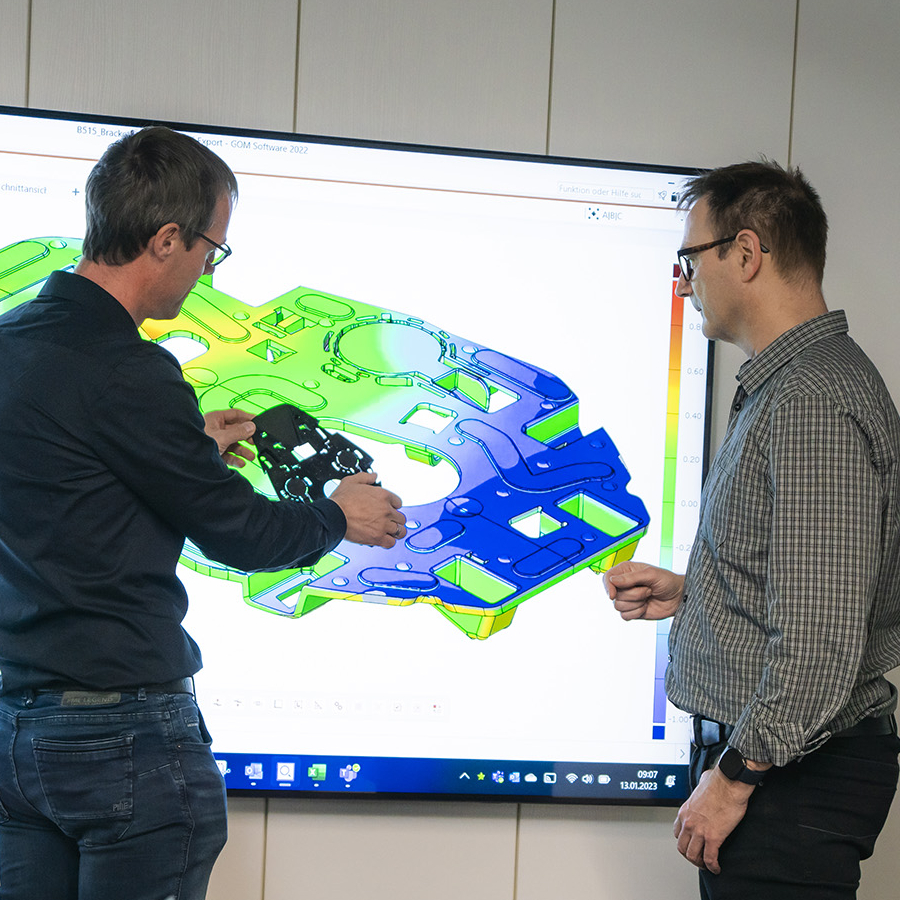

3D data is read in with the Siemens/NX CAD system and enables perfect visualisation of the product and the appropriate tool. The mouldflow analysis allows our mould designers to detect possible problem areas at a very early stage in the creation of the injection mould and to design the best fitting solution.

In so-called rapid prototyping, our customers have the opportunity to obtain initial results in 3D printing, among other things, in order to test design and functionality. For this, our external partners are a guarantee for perfect sampling in order to detect possible error potentials at an early stage and to ensure that the subsequent series production runs smoothly.

Prototypes as stereo laser lithography, laser sintered parts or vacuum casting are also possible in every phase of development.This results in flawless objects that form the basis for a production-oriented design of the tools that ensure a high-quality result.

Small series are quite useful to produce the first near-series samples from the original series material with pre-series tools. The surface finishing and assembly of the first parts, including the initial sample test report, are of course part of our service on request.