Product development

Collaborative product development is the basis for a perfect result

In close cooperation with the product developer, all preparations are discussed that lead to an optimal result.

We incorporate our expertise right from the article design stage in order to achieve a plastic-compatible design. Further development of existing designs also leads to a better process during the production phase and ultimately to better quality. This optimises both functionality and the design of the tools. We help our customers with material selection and use our material expertise to make the best recommendation for the project.

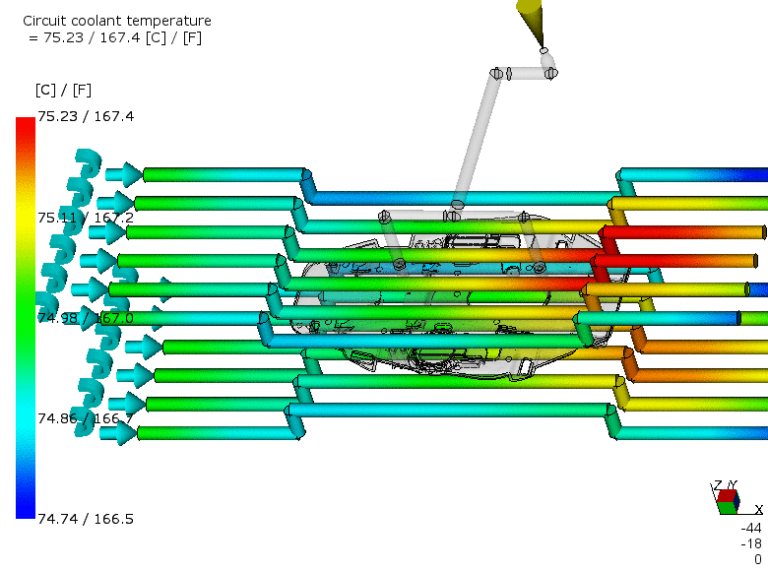

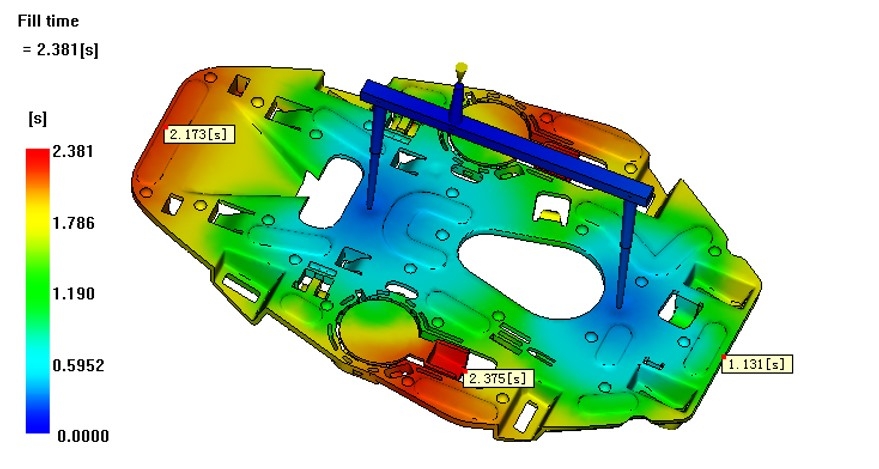

Thanks to precise simulation, both the product and the mould geometry are optimised. This guarantees a stable and qualitative flow during the injection process. For this purpose, common software tools such as Cadmould® are used to simulate and visualise the filling pattern, pressure distribution or flow speeds. The forces on the slide, the aeration and cooling time are also calculated.

Already during the development phase, we discuss the possible surface treatments and together we find the best technique to give the final product a perfect finish, depending on the design requirements and field of application. In addition to our own finishing options, we work with specialists who enable us to use a variety of surface techniques.

Beyond the production of individual parts, we develop assembly concepts with our customers for the completion of entire assemblies.